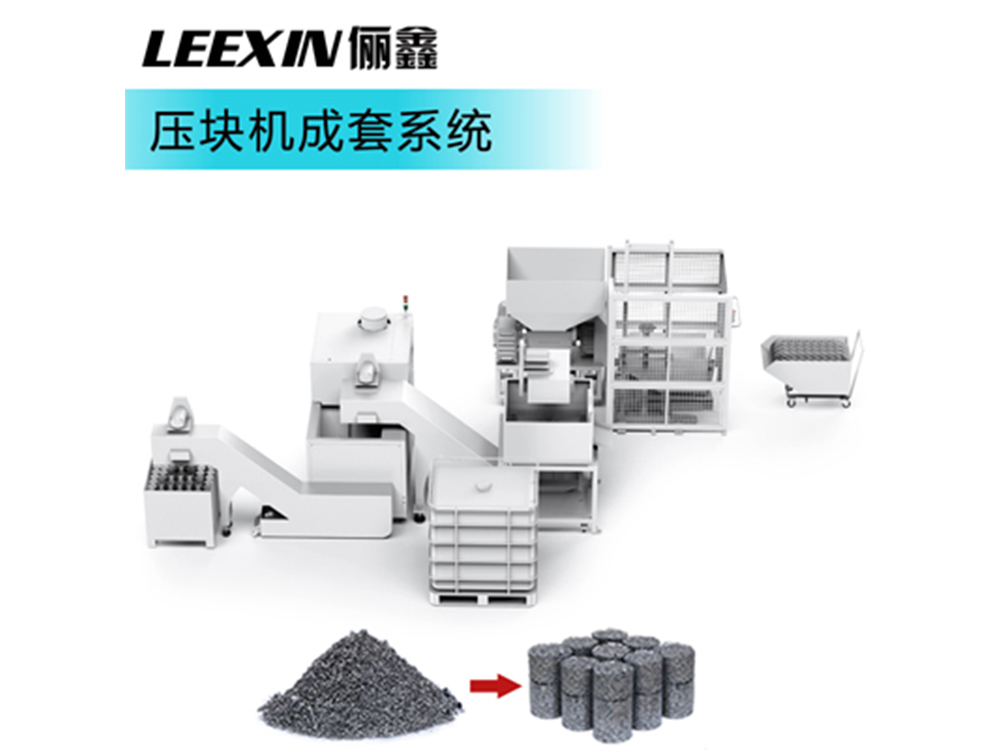

Metal chip briquetting machine is a mechanical equipment that can press various particles, cast iron, aluminum, copper, magnesium, titanium, molybdenum and other metal chips into high-density briquettes without any additives.

The metal chip briquetting machine adopts full hydraulic control, and the electrical main control part adopts PLC control. The whole working process can be automatically operated. Without adding any additives, various particles, cast iron, aluminum, copper, magnesium, titanium, molybdenum, etc. can be pressed into high-density briquettes and directly put into the furnace for smelting, which greatly reduces the cost.

The electrical part of the metal chip briquetting machine adopts PLC control, which has strong anti-interference ability, high degree of automation and simple operation. The hydraulic station adopts integral inherited valve block and chasing through the installation valve, which eliminates oil leakage, reduces the oil temperature of the system and improves the stability of the system. The frame part adopts integral cast steel parts, which eliminates the cracking of steel plate weldments and improves the reliability, stability and service life of the equipment.

The cylinder adopts tandem cylinder to improve the movement speed and production efficiency. According to the working conditions of the user, the spiral automatic feeder and chain automatic feeder are adopted to reduce the labor intensity of the workers. The metal chip briquetting machine is divided into vertical and horizontal structures.